Services

We have now extended our services include custom slotting and coating in our engineering warehouse in Melbourne, Australia for all size rotors and flywheels.

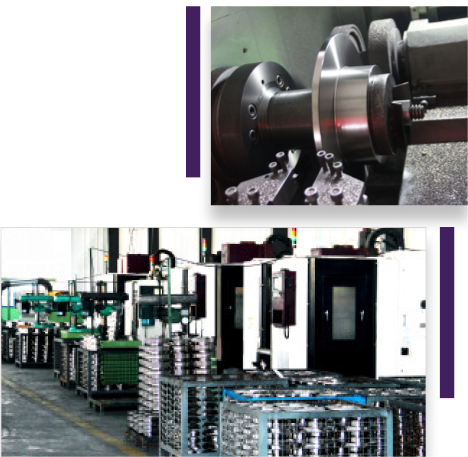

Delios, with its origins in aerospace engineering, brings a high level of technical sophistication to the design and manufacture of advanced braking systems. Leveraging over two decades of engineering expertise, Delios offers a unique capability for customised brake solutions through the use of precision CNC lathes and milling machines. This advanced manufacturing infrastructure allows for the production of bespoke brake rotors, callipers, and pads, tailored to meet specific performance criteria in demanding applications such as 4WD and high-performance vehicles.

Our engineering process integrates precise metallurgical formulations, proprietary casting techniques, and advanced machining to ensure superior thermal resistance, enhanced structural integrity, and optimised performance. Whether designing upgrades for existing systems or creating fully customised braking components, Delios’ technical depth enables us to achieve highly specific tolerances, ensuring components that are fine-tuned for maximum efficiency, durability, and thermal stability. This capability allows us to push the boundaries of braking technology, delivering not only tailored solutions but also significant performance enhancements that meet the rigorous demands of modern vehicles.

Delios extends its engineering expertise beyond the automotive industry, offering tailored solutions across various sectors. With a focus on collaboration, we work closely with clients to develop precision-engineered components and systems that meet unique operational requirements. Whether for aerospace, heavy machinery, or other high-performance industries, Delios utilises advanced CNC capabilities and cutting-edge design methodologies to deliver bespoke solutions. Our approach emphasises a partnership-driven process, ensuring that we understand specific challenges and co-create solutions that optimise performance, efficiency, and reliability across diverse applications.

Please feel free to reach out if you have any ideas that you would like to make into reality. We're here to collaborate and transform concepts into engineered solutions that meet your unique needs.

Why use Delios Pty Ltd for custom slotting and coating?

- We slot to improve performance and efficiency while taking great care not to add material stress (mass produced slotting is just that, massed produced. This often leads to increased internal material stresses ,which can lead to warping, cracking and harmonics)

- Every slot has been specifically designed to each particular rotor. We have over 5000 part programs.

- All rotors receive secondary inspection of thickness, porosity, corrosion and slag in vents.

- Coating is environmentally friendly and is not limited by temperature range; it will not peel, even in extreme temperatures. We ensure that all our coating process is done individually for premium results.

- Increase your range of slotted rotors without the large MOQ, while decreasing your stock in hold.

- Quick turnaround. Most slotting can be done on the day. Discounts for larger bulk slotting apply (Turn around may vary depending on volume).

- We can turn a slotting idea into your slotting reality. We do custom slotting. This can be custom to your range and exclusive (we respect proprietary information and protect it as if it was our own). We maintain all slots within ADR limits and will not cross drill or allow any other risky slotting to be performed(we feel that while maintain the integrity of our work, we are protecting our customers interests)

All information is Private and Confidential under copy right and trademark Delios Pty Ltd©™ and is not permitted to be copied or transmitted through any correspondence unless written and exclusive permission is obtained.

Taxi &

Fleet Services

Delios Brakes are used and trusted by taxi depots and fleet services around Australia.

Please feel free to contact us for further information.

英語

英語 西班牙語

西班牙語